ESI’s Project Gallery

Our breadth of experience spans coast to coast and border to border

Since 1996, ESI has installed BILLIONS of square feet of geosynthetic liner systems across the United States. That’s more than 2,000 environmental containment projects over the last 20 years in the solid waste, coal ash (CCR), industrial, mining and related markets.

The gallery below is a small sample of the total number of projects we have completed. As we have done for the projects shown below, ESI can meet your company’s need for material supply and installation of geosynthetic materials and HDPE piping systems, for your environmental containment application. Through our 20 years of business, we have developed a highly skilled and experienced workforce of nearly 400 employees who safely and efficiently complete projects on-time, with the highest level of quality.

Use the menu options on the bottom-left to filter projects based on solution or market.

- MARKETS

- - POWER CCR

- - Solid Waste

- - Oilfield

- - Natural Gas Storage

- - Petrochemical

- - Industrial

- - Mining

- - Aqua and Agriculture

- SOLUTIONS

- - Geosynthetic Closure System

- - Geosynthetic Liner System

- - HDPE Pipe Fusion

- MATERIALS/SYSTEMS

- - Conductive Liner

- - Synthetic Turf

- - Wind Defender

- - Drainage Layer

- - Secondary Containment

Geosynthetic Conductive Liner | Energy Transfer Partners NGL Brine Pond

ESI provided materials and the installation of an 18-acre double-liner composite system for this natural gas storage pond in Mississippi for Primoris Services Group (the project GC). A geocomposite gas venting layer was placed directly on the subgrade with an 80-mil white conductive liner, geonet drainage layer, topped with an 80-mil smooth HDPE white conductive liner. The customer requested the two conductive liner layers as added protection against pinholes and leaks. The customer also asked ESI to weld water level measurements on the slope as shown in the picture on a textured 60-mil HDPE liner that served as a walkway. ESI also fused and installed more than 3,000 LF of HDPE pipe system to complete the drainage system.

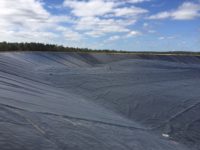

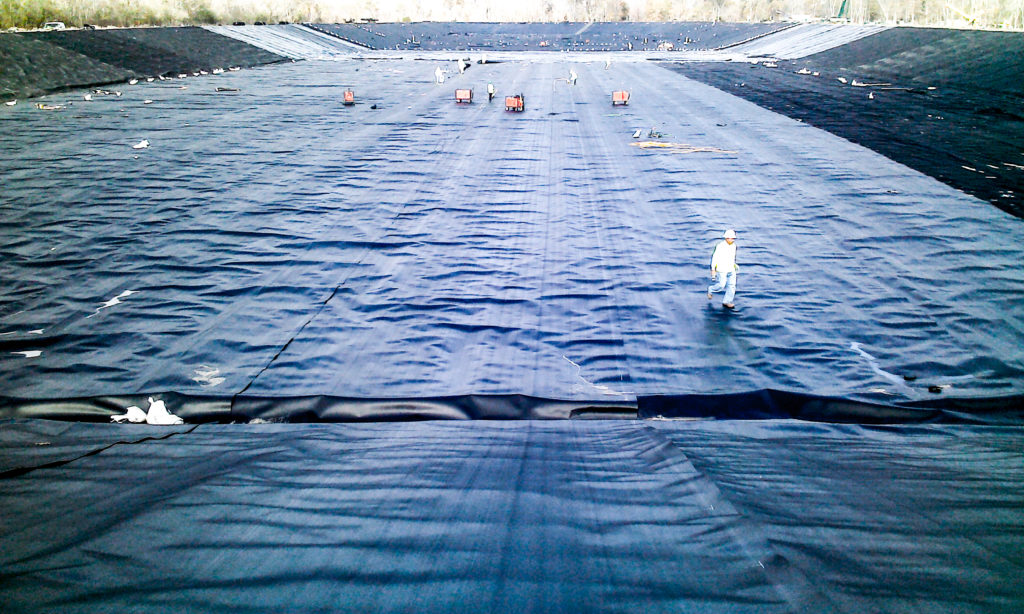

Geosynthetic Liner System | Haile Gold Mine

ESI recently completed the installation of a geosynthetic lining system for Morgan Corp – the general contractor for the construction of a 328-acre tailing pond for a gold mine in South Carolina. The exciting project was completed over a five month period and was another great example of how teamwork and partnering can deliver an extremely successful marquee project.

The project manager for Morgan Corp had this to say about ESI:

“I wanted to let you know how much we appreciate ESI joining our team here at Haile and making this such a successful project. I had my doubts as to whether we could pull off 328 acres in 5 months, but you did not disappoint! I can’t express how great Arizona and his crew were to work with. They are some of the hardest working guys (and gal) I’ve ever been around, and Arizona’s leadership skills are second to none. I can’t say that we would have accomplished our goals on schedule without his vision and help in planning, and for that Morgan is very grateful.”

Ben Boland, PE, Project Manager

Morgan Corp

Geosynthetic Cover System | Savannah River Coal Ash (CCR) Site

As sub to the General Contractor (Envirocon), ESI recently installed the geosynthetic lining system used to close a coal ash basin at the U.S. Department of Energy’s (DOE) Savannah River site in South Carolina. Our work consisted of installing a Geosynthetic Clay Liner (GCL) and Double-Sided Drainage Geocomposite at this 21.5 acre site.

ESI’s project team confronted many challenges in order to complete the project, including the need to manage through two tropical storms (Bonnie & Colin) that disrupted the construction.

We were able to overcome these obstacles safely and efficiently under the leadership of Field Superintendent Ali Malimar and his crew.

Composite Liner System | DOE's Washington Hanford Facility

Composite liner installation for the DOE's low-level radioactive waste site (Washington Hanford Facility) located in Richland Washington. ESI installed a 40 acres composite liner system - 60 Mil HDPE white secondary liner, leak detection zone and 60 Mil HDPE white primary liner.

Geosynethetic Base Liner & Cap System | Malone Superfund

The Malone Service Company Superfund Site is located in Texas City, Texas, near the shore of Galveston Bay. The facility operated from 1964-1997 as a reclamation, storage, and disposal facility for waste oil and chemicals. ENTACT who is responsible for the clean-up and remediation of this closed facility. ESI was subcontracted by ENTACT to install a double liner system in a 3.2 acre storm water pond (40 Mil Polypropylene), 30 acres of double lined cells for waste (80 Mil, GCL & composite) then 30 acre cap (40 Mil, GCL & composite).

ClosureTurf Synthetic Grass Closure | Saufley Landfill

Escambia County, FL inherited the Saufley Landfill, a 23-acre construction and demolition landfill known for environmental issues related to the original closing and capping of the site. In 2006, it was labeled an environmental risk. The county researched solutions and chose to install a 25-acre ClosureTurf® system that would permanently cap the landfill, control gas emissions, deliver clean storm-water runoff, and provide a pleasing green appearance to the site while reducing ongoing maintenance costs. ESI was awarded the business to install the advanced turf closure system, completing the project in 2012.

The project was awarded the 2014 Silver Award of Excellence for Landfill Remediation by the Solid Waste Association of North America (SWANA).

New Cell Expansion | SPSA Regional Landfill

ESI was awarded a new cell expansion as General Contractor and Geosynthetic Liner Installer for the State of Virginia's Southeastern Public Service Authority in Suffolk, VA

As part of the project requirements, ESI prepared 20 acres of subgrade and installed over 1,000,000 sf of GCL, 2,000,000 sf of composite and 2,000,000 sf of HDPE liner, with protective cover. In addition, we were contracted to install leachate & groundwater HDPE piping with collection trenches.

ESI received additional incentives on this project due to early completion.

Secondary Liner System | Exxon Mobil Baton Rouge Refinery

ESI completed the secondary containment liner system required for two (2) new above ground biox liquid storage tanks at the Exxon Mobil Refinery (Project Tanks 303A and 303B) located in Baton Rouge, Louisiana. Each of the biox tank foundations were 200’ in diameter and was subdivided into an outer foundation ring and inner foundation ring. ESI utilized 100 Mil HDPE geomembrane liner to complete the foundation secondary containment liner systems required for each of the biox tanks. A 6” wide HDPE sealock strip was cast into each of the concrete ring wall foundations for attachment of the 100 mil HDPE liner to the perimeter foundations. ESI also supplied and fusion welded the 3” HDPE leak detection pipes and fabricated leak detection sumps installed on the outside of each of the tank foundation. ESI was a subcontractor to Cajun Constructors, LLC. from Baton Rouge, Louisiana.

Firewater HDPE Piping System | Honeywell Apollo 2 Project

ESI supplied and installed approximately 4,000 LF of HDPE Factory Mutual firewater piping system ranging in size from 6”-12” as part of Honeywell’s Apollo 2 expansion project at the facility located in Geismar, Louisiana. The firewater system expansion project included installation of new fire hydrants, fire monitors, post indicator valves ranging from 10”-16” in size and six (6) new air release valves. ESI fusion personnel completed all HDPE pipe welding, valve boltups and hydrostatic testing of the new firewater piping system installed for the expansion project. ESI completed all of the HDPE pipe fusion and testing work in conjunction with earthwork activities being completed by Beard Construction Group.

Geosynthetic Liner & HDPE Piping System | Alcoa/Reynolds Metals Hazardous Waste Landfill

ESI completed an expansion project for ALCOA-Reynolds Metals site as part of their hazardous waste-industrial waste landfill system at the facility located near Arkadelphia, Arkansas. ESI supplied and installed approximately 1,142,526 SF of 60 mil textured HDPE geomembrane liner, 571,263 SF of double sided geocomposite, 571,263 SF of 12 OZ Non-woven geotextile and 571,263 SF of 8 OZ Non-woven geotextile required for completion of landfill Cells 9 & 10. ESI also completed approximately 2,600 LF of 6” HDPE leak detection piping, 2,840 LF of HDPE leachate collection piping, extension of the 6”/10” HDPE dual contained leak detection forcemain piping, extension of the 8”/12” HDPE dual contained leachate collection forcemain piping, fabrication/installation of two (2) 36” HDPE vault structures and tie-in connections to the existing leachate collection tanks. ESI completed the geosynthetics and HDPE piping installation working with the general contractor Pollution Management, Inc. from Little Rock, Arkansas.

Pond Liner | Carolina First Corporate Campus Pond

Four acres of CETCO AKWASEAL was installed as a water barrier for this project. ESI worked with the general contractor (Grambling Contracting, Grambling, SC) to complete the project. The project is a recognizable and environmentally sustainable corporate campus on a former 65-acre brownfield site and has been awarded LEED-NC Gold for the site.

HDPE Piping System | Exxon Mobil Rockwell Plant

ESI supplied and installed approximately 3,400 LF of HDPE piping ranging in size from 12” to 24” as part of Exxon’s Rockwell Plant expansion project at the Port Allen lubrication facility in Louisiana. The HDPE piping installation was completed as part of the firewater piping system expansion and completion of new drainage piping in the expansion area. ESI supplied all HDPE pipe and fittings required on the project. All of the HDPE piping systems were hydro-tested and service tested prior to backfilling of the excavations. ESI was subcontracted by Cajun Constructors to complete this project.

Wastewater Digester | Conagra's Lamb Weston Facility

ESI completed a liner system installation required for an anaerobic wastewater digester at the Conagra Lamb Weston facility located in Delhi, Louisiana. ESI installed approximately 248,675 SF of 80 Mil HDPE white conductive geomembrane liner within the new digester. The 80 Mil geomembrane liner system was electrically spark tested using the electrical arc testing method. 100% of the membrane surface was tested to ensure a completely leak free installation. The geomembrane liner system was attached to the digester concrete containment walls utilizing a combination of stainless steel battening, GSE HDPE sealock strips and GSE HDPE stud liner material cast into the concrete walls. ESI completed this project working directly for Con Agra Lamb Weston working in conjunction with a general contractor on the site.

New Cell Construction | Twin Chimneys Landfill

Twin Chimneys Landfill is located on 1,155 acres in southern Greenville County, South Carolina. The municipally owned landfill is a state of the art Subtitle D landfill designed to handle municipal solid waste generated in and around the county.

Geosynthetic Conductive Liner | Petro Logistics Choctaw Brine Pond

As subcontracted by Beard Construction, ESI installed a conductive geosynethetic liner for Petro Logistic's Choctaw Process Brine Pond in Plaquemine, LA. ESI's scope was to install 11 acres of 60 Mil Textured HDPE Conductive Liner with Geotextile and Geonet. The entire liner system was spark tested to ensure leak proof protection.

HDPE Leachate Collection Piping System | Georgia Pacific's East Landfill

ESI completed the leachate collection piping system for Phase 1 of the East Landfill which included 1920 LF of 8” HDPE perforated leachate laterals and cleanout piping, 480 LF of 10” HDPE perforated leachate laterals, 590 LF of 24” HDPE Solid/Perforated leachate riser piping and 3,760 LF of 18” HDPE Leachate forcemain piping at the Georgia Pacific Monticello, Mississippi Facility. All work was completed by ESI fusion personnel working in conjunction with ESI liner installation personnel at the site. ESI also installed approximately 330,000 SF of 60 Mil HDPE Smooth/Textured liner, 24 Oz. non-woven geotextile and geosynthetic clay liner (GCL) as part of construction of the Phase 1 landfill. All of the 18” and 24” leachate forcemain piping was hydrostatically pressure tested to ensure leak free service for Georgia Pacific. ESI completed all of the HDPE piping work and geosynthetics installation working with Pickett Industries as the civil/earthwork contractor.

Brine Pond Liner | Enterprise Products Partners, Section 28

Under the direction of Beard Construction Group, ESI was commissioned to install over four million sf of geosynthetic materials to complete this liner system for Enterprise Product's Brine Pond #8 in Martinville, LA. The system featured 40-Mil Smooth, 60-Mil Smooth and Textured HDPE Conductive Liners, including Geonet, 24 oz Non-Woven Geotextile. HDPE pipes and fittings were fabricated and installed by ESI to allow for groundwater collection and influent, and leak detection.

New Cell Construction | Georgia Pacific's Savannah River Mill

This six acre industrial landfill cell expansion in Rincon, GA for Georgia Pacific, featured a 60-mil textured HDPE geomembrane liner and 12 oz non-woven geotextile layer with tie-in welding to previous construction, extrusion welding of stormwater containment flaps and the completion of thirteen (6”) pipe penetrations through the geosynthetic liner system. ESI provided the contracted services directly to Georgia Pacific to complete this project.

Secondary Containment | Kinder Morgan Geismar Methanol Terminal

This secondary containment project involved the installation of nearly 10 acres of 60-mil textured HDPE geomembrane, 16-oz. Non-Woven Geotextile and Geogrid to complete the geosythetic liner system for a detention pond and the tank containment dike. ESI was the subcontractor on this project to Beard Construction Group.

Composite Liner System | Waste Management's Columbia Ridge Landfill

Located in central Oregon, Waste Managment's Columbia Ridge landfill opened in 1990 and currently has 700 permitted acres. ESI's involvement at this site was to install a multi-layer composite liner system that included an engineered clay barrier and a 60-mil high-density polyethylene (HDPE) membrane to ensure that waste and wastewater (leachate) are contained and isolated from soil and groundwater.

Pond Liner | Louisiana Department of Wildlife and Fisheries' Beechwood Fish Hatchery

Beard Construction awarded ESI a project to install the geosynthetic lining system at sixteen one-acre sites for the Louisiana Department of Wildlife and Fisheries in Forest Hill, LA. Materials installed included reinforced TAN 45-mil polypropylene liner, 6-ounce non-woven geotextile, 8-ounce woven geotextiles.

Exposed Geomembrane Cover | US Ecology

ESI has installed a number of cell expansions and closures at this site in Belleville, MI. This photo was taken at US Ecology's cells 6 & 7 which was a 5.7 acre closure project that involved installing a 40-mil HDPE liner including tie-in welding to the existing liner system. Note the pillow ballasts.

ClosureTurf Synthetic Turf Cover | Louisa County Solid Waste Landfill

Louisa County wanted to reduce the operating costs associated with maintaining natural grass cover, repairing slope erosion, and removing silt in stormwater ditches and sediment basins for their 14-acre, unlined sanitary landfill in Mineral, Virginia, This closure of this municipal solid waste landfill featured a synthetic cover system installed by ESI. The cover system is a synthetic turf system named ClosureTurf® manufactured by WatershedGEO. The system involved the installation of 50-mil Super GripNet®, ClosureTurf with sand ballast and Hydro-Turf.

Sedimentation Basin | Mary Rhodes Pumping Facility

ESI was contracted by Oscar Renda Contracting, Inc (GC) to install a 60-mil textured HDPE geomembrane liner and the geocomposite drainage layer required for construction of the sedimentation basin project for the city of Corpus Christi, TX.

HDPE Piping Upgrades | Mosaic Fertilizer

ESI supplied and installed approximately 1,120 Linear Feet of HDPE pipe ranging in size from 2” to 12” as part of Mosaic Fertillizer's RO units upgrade project in Uncle Sam, Louisiana. The project included the addition of three (3) new media containers, two (2) new RO containers, one (1) RO permeate storage tank and a new pump skid. The equipment mechanical piping installation included all associated HDPE fittings, installation of fifteen (15) stainless steel valves and all mechanical connections to the new RO equipment being installed by Mosaic personnel, pump skid and existing unit piping. All work was performed by ESI fusion personnel working directly with Mosaic operations and maintenance personnel. Upon completion of the installation the new mechanical piping system was pressured and tested prior to startup of the new RO units equipment.

Composite Liner System | Shoosmith Landfill

Virginia Waste Services is a privately owned waste company specializing in commercial and industrial waste disposal in the Richmond, VA area. The company contracted ESI for a 6-acre new cell expansion at their Shoosmith landfill in Chester, VA. ESI installed 60-mil HDPE textured geomembrane, geocomposite and geosynthetic clay liner to complete the base liner for the landfill.

Geosynthetic Conductive Liner System | Enterprise Wilson Ethane Storage Brine Pond

ESI installed over 6 acres of 40 Mil and 60-Mil White/Black Conductive HDPE Liner with HDPE Geonet for Enterprise Product's brine pond in Boling, TX. The entire system was spark tested to ensure leak proof integrity. ESI performed this work as the subcontractor to Beard Construction.

Geosynthetic Liner Closure | TVA's Widows Creek Gypsum Stack Landfill

Morgan Corp contracted ESI to install a geosynethetic liner system as part of the final closure system for this 130-acre site located in Jackson County, AL. The liner system included a 40-mil LLDPE textured geomembrane and geocomposite for drainage.

Geosynethetic Final Closure | Santee Cooper CCR Landfill

Our project at Santee Cooper (Pineville, SC) consisted of installing 60-mil WHITE textured HDPE, geocomposite and geotextile and geosynethetic clay liner for final closure, under the direction of Morgan Corp (GC).

Geosynthetic Lining System | AEP Northeastern Station (CCR) Landfill

ESI was contracted by Charah, Inc to install geosynthetic lining systems for purposes of final closure of a coal combustion residual (CCR) landfill at AEP's Northeastern Station in Oologah, Oklahoma. The materials involved included the installation of 60-mil HDPE textured geomembrane, double-sided geocomposite, geosynthetic clay liner and non-woven geotextile in various assemblies to complete the facility required for proper environmental protection.

Geosynthetic Liner System | TVA Kingston

ESI supplied and installed a 60 Mil Textured HDPE Liner and a double-sided composite as a drainage layer at this 26 acre Coal Combustion Residual cell expansion at TVA in Kingston, TN.

Geosynthetic Conductive Liner | Cardinal Gas Brine Pond

Ten acres of 60 Mil White/Black Conductive HDPE Liner with HDPE Geonet and Geo-Composite was installed by ESI for this Brine Pond owned by Cardinal Gas. The entire liner system was spark tested to ensure leak proof integrity. ESI installed the liner system for Beard Construction, the project GC.